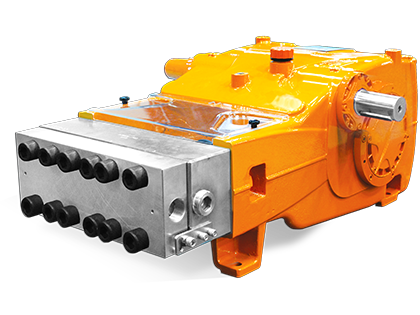

The NLB 125 Series pump is an advanced design triplex pump with exceptional flexibility and versatility to efficiently meet the requirements of a wide range of pumping services. The unit features a simple, rugged design to meet the heavy-duty requirements of continuous operation and to minimize maintenance.

The 125 pump is available with either an internally or non-internally geared power end. (Click on the links to view the brochure for the version you are interested in.)

Fluid End Features Include:

- Easily configured for operating pressures from 6,000 to 40,000 psi in under 20 minutes.

- A single stainless steel frame plate and swing-out manifold is used for all operating pressures.

- The design features minimum volumetric clearance and stress, with maximum shock and pressure resistance.

- Passages are drilled to minimize turbulence.

- The valve seat and stuffing boxes are precision-machined from high-grade stainless steel.

- Stainless steel valves have a rugged, double guided design that improves valve life by ensuring alignment. Seats are beveled and are also made from hardened stainless steel.

- Pump features Colomony®-coated plungers for 6-10K operation and solid tungsten carbide plungers for 15-40K operation.

Power Frame Features include:

- Horizontal configuration provides easy access and low center of gravity.

- Rugged, cast-iron housing with gravity lubrication and large oil reservoir.

- Forged steel crankshaft mounted in heavy duty bearings.

- Drive pinion output shafts on both sides of pump allow for opposite-hand drive. (G Version)

- Internal gearing eliminates the need for large pulleys or belts, greatly decreasing the pumps overall footprint. (G version)

- Large-diameter cylinder crossheads operating in full circular guides, fitted with hardened wrist pins

- Ground crosshead stub shafts with lipped seals to keep water and dust out of crankcase.

- High mechanical efficiency.

- Plunger cover for cleanliness and operator protection.

| Part Number | Plunger Dia. | Pump RPM | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | Max. Pressure | ||||||||||

| IN | MM | GPM | LPM | GPM | LPM | GPM | LPM | GPM | LPM | GPM | LPM | PSI | BAR | ||

| 40125-9/16 | 9/16 | 14.3 | 0.97 | 3.7 | 1.94 | 7.3 | 2.91 | 11.0 | 3.88 | 14.7 | 4.85 | 18.4 | 40,000 | 2,800 | $1 Get a Quote |

| 40125G-9/16 | $1 Get a Quote |

||||||||||||||

| 35125-19/32 | 19/32 | 15.87 | 1.11 | 4.2 | 2.22 | 8.4 | 3.33 | 12.6 | 4.44 | 16.8 | 5.55 | 21.0 | 35,000 | 2,415 | $1 Get a Quote |

| 35125G-19/32 | $1 Get a Quote |

||||||||||||||

| 24125-3/4 | 3/4 | 19.05 | 1.6 | 6.1 | 3.2 | 12.3 | 4.9 | 18.4 | 6.5 | 24.5 | 8.0 | 30.3 | 24,000 | 1,656 | $1 Get a Quote |

| 24125G-3/4 | $1 Get a Quote |

||||||||||||||

| 20125-13/16 | 13/16 | 20.64 | 1.9 | 7.3 | 3.9 | 14.7 | 5.8 | 22.0 | 7.8 | 29.4 | 10.0 | 37.9 | 20,000 | 1,380 | $1 Get a Quote |

| 20125G-13/16 | $1 Get a Quote |

||||||||||||||

| 15125-15/16 | 15/16 | 23.81 | 2.6 | 9.8 | 5.2 | 19.5 | 7.7 | 29.3 | 10.3 | 39.1 | 13.0 | 49.2 | 15,000 | 1,035 | $1 Get a Quote |

| 15125G-15/16 | $1 Get a Quote |

||||||||||||||

| 10125-1-1/8 | 1-1/8 | 28.58 | 3.9 | 14.7 | 7.8 | 29.4 | 11.6 | 44.1 | 15.5 | 58.7 | 19.5 | 73.8 | 10,000 | 690 | $1 Get a Quote |

| 10125-1-1/8 | $1 Get a Quote |

||||||||||||||

| 8125-1-1/4 | 1-1/4 | 31.75 | 4.9 | 18.4 | 9.7 | 36.7 | 14.6 | 55.1 | 19.4 | 73.4 | 24.5 | 92.7 | 8,000 | 552 | $1 Get a Quote |

| 8125G-1-1/4 | $1 Get a Quote |

||||||||||||||

| 6125-1-1/2 | 1-1/2 | 38.1 | 6.5 | 24.5 | 12.9 | 48.9 | 19.4 | 73.4 | 25.8 | 97.8 | 32.5 | 123.0 | 6,000 | 414 | $1 Get a Quote |

| 6125G-1-1/2 | $1 Get a Quote |

||||||||||||||

Social Media

TwitterFacebookYoutubeLinkedinInstagram